CASE STUDY

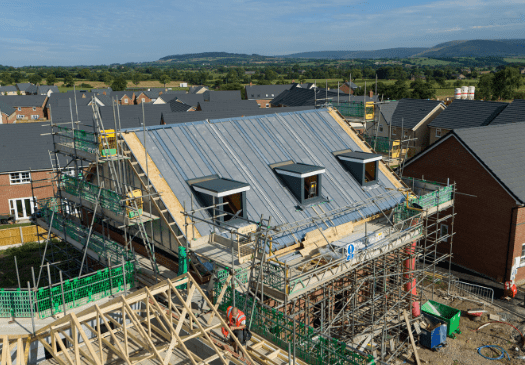

Bowland Meadow, Preston

Install Time: 3 roofs in 3 days

Client: Barratt Homes

Barratt Homes had been closely involved in the development of the Ultrapanel system and are now rolling it out on live sites such as Bowland Meadow.

The Ultrapanel ‘room in the roof’ and spandrel wall solution was used on the Kingsville house type – a three-storey terraced home.

Barratt Developments is the UK’s number one volume housebuilder and like Ultrapanel Building Technologies, is an innovation led company, always keen to utilise the latest technology in its homes to ensure the optimum building process and customer satisfaction. In fact, Barratt Developments has been the UK’s most recommended housebuilder for 12 years in a row, earning the company a 5-Star rating with the Home Builders Federation.

FULLY ACCREDITED

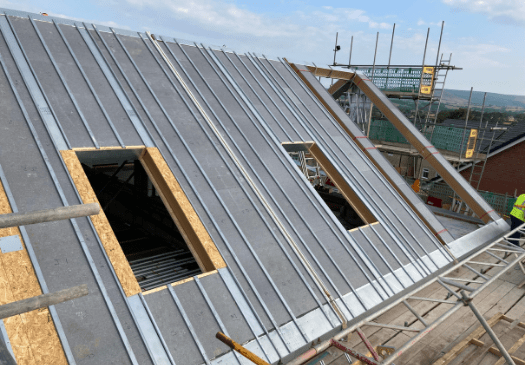

The Ultrapanel ‘room in the roof’ system is BBA and NHBC accredited for total peace of mind and future proofed to meet new legislation requirements.

TOTAL DESIGN FLEXIBILITY

The Ultrapanel system allows for windows (and staircases) to be placed virtually anywhere in a house design, which floods the space with huge amounts of natural light. On this house the Ultrapanel roof was able to replicate the existing design without any changes. Although in the future to take full advantage of the system, the design could include a valuted ceiling for example.

RAPID INSTALLATION

On this build, each plot was watertight within a day, saving a huge amount of time compared to a traditional roof build. No crane is needed, thanks to its lightweight nature which eliminates the complexities of having a crane on site, along with reducing H&S risks due to heavy lifting at height.

SITE FRIENDLY

Thanks to an established, reliable and responsive supply chain, each Kingsville roof was delivered to site in kit form within 2 weeks of call-off, meaning no delays on site, and an acceleration of the build schedule.

Don’t just take our word for it...We started this journey with Ultrapanel almost two years ago. They came to us with a very unique roofing system, different in both its structure and its approach to build. As always, as Barratt, we are very interested in new innovations – especially ones that change the key dynamics of how we approach construction. We have done a very detailed review as you can imagine over the last two years of the Ultrapanel system, trialing it in their factory and on site. Part of our NPI process is that we assess every step of the technology in its application to ensure it meets the demands of construction sites, our customers most importantly, and ourselves at Barratts.

Oliver Novakovic, Technical & Innovation Director - Barratt Developments